Scour Valve Symbol: Complete Guide for Beginners

In engineering and pipeline design, every tiny symbol tells a story. One such important yet often misunderstood symbol is the scour valve symbol. Whether you’re a student learning piping symbols, a technician reading water network drawings, or an engineer preparing P&ID diagrams, understanding this symbol is essential.

In this detailed guide, we’ll break down everything you need to know about the scour valve symbol—its meaning, purpose, design representation, and practical applications. Let’s dive in.

What Is a Scour Valve?

Before understanding the symbol, let’s first clarify what a scour valve actually is.

A scour valve, also known as a drain valve or blow-off valve, is a special type of valve installed at the lowest point of a pipeline or water system. Its primary purpose is to drain water, sludge, or sediment that settles at the bottom of pipes, tanks, or reservoirs.

In simpler terms, it helps clean out or flush the system — keeping the water clean and preventing blockages or contamination.

Main Functions of a Scour Valve

Draining pipelines during maintenance or shutdowns.

Flushing sediments and debris from the bottom of the pipe.

Preventing corrosion and buildup inside water mains.

Maintaining system hygiene in potable water systems.

Ensuring pipeline efficiency and preventing damage over time.

Why the Scour Valve Symbol Matters

Engineering drawings use hundreds of symbols to represent complex systems simply. The scour valve symbol helps professionals quickly identify where and how water can be drained or flushed from the system.

Without clear symbols:

Maintenance crews might miss crucial drain points.

Engineers could misinterpret pipeline functions.

The risk of design errors increases dramatically.

That’s why the scour valve symbol is an essential element of piping and instrumentation diagrams (P&ID), water network drawings, and civil or mechanical layouts.

Scour Valve Symbol in Engineering Drawings

In Piping and Instrumentation Diagrams (P&ID)

In P&ID diagrams, a scour valve is typically shown as a valve symbol connected to the lowest portion of a main pipeline or tank outlet.

It’s often drawn as:

A globe valve or gate valve symbol.

Connected through a branch line going downward.

Sometimes labeled as “SV” or “Drain”.

Example (Text-based representation):

Main pipeline ─────────┬─────────

|

(SV)

|

Drain

Here, (SV) represents the scour valve symbol, positioned to discharge the flow downwards for draining or flushing

In Water Distribution Drawings

In water supply or irrigation drawings, the scour valve symbol is generally represented by a small valve mark placed at the lowest elevation point of a pipeline section.

The symbol might vary slightly depending on the standard used:

BS (British Standard) symbols differ slightly from ISO or ANSI standards.

Some utilities use a circle with a cross and label it “Scour Valve” or “S.V.”

Typical Notations:

SV – Scour Valve

DV – Drain Valve

BFV – Blow-off Valve

Scour Valve Symbol Variations by Standard

| Standard | Symbol Style | Description |

|---|---|---|

| ISO 14617 | Valve symbol with a drain line | Commonly used in industrial and mechanical piping |

| BS EN 806-4 | Circle + label “S.V.” | Common in civil and water drawings |

| ANSI/ISA 5.1 | Control or manual valve symbol with downward discharge | Often used in process industries |

| Municipal Drawings | Simple valve symbol near a manhole or washout | Seen in water distribution systems |

The symbol design may differ slightly, but the function remains the same — allowing controlled discharge of unwanted materials from a system.

How a Scour Valve Works

The operation of a scour valve is simple but crucial.

Normal Operation:

The valve remains closed during regular system flow to prevent loss of water.

Maintenance or Flushing:

When the system needs cleaning, the valve is opened manually or automatically, allowing water, sediments, and air pockets to flush out through the outlet.

After Draining:

Once flushing is complete, the valve is closed again to resume normal flow.

In large systems, scour valves are often connected to drainage sumps, open channels, or stormwater systems to safely discharge the flushed water.

Types of Scour Valves

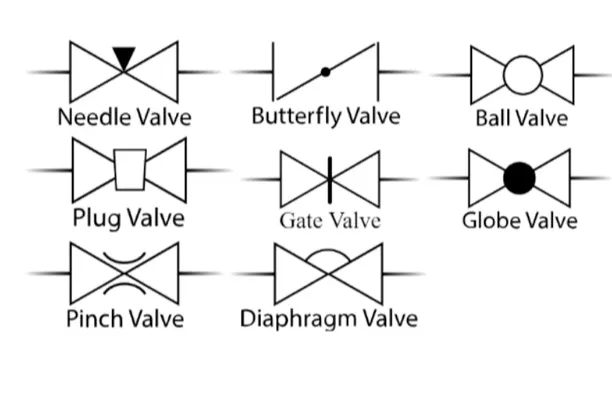

Depending on the application and system pressure, different types of scour valves are used — each represented by slightly modified symbols in diagrams.

Gate Valve Type

Common in water pipelines.

Simple on/off control.

Represented by the standard gate valve symbol with a downward outlet line.

Globe Valve Type

Used when precise flow control is needed.

Common in industrial systems.

Represented by a globe valve symbol.

Butterfly Valve Type

Compact and lightweight design.

Used in medium-pressure systems.

Shown with the butterfly valve symbol.

Ball Valve Type

Provides full bore flow and quick operation.

Symbolized as a circle with a handle line.

Placement of Scour Valve in a System

The placement of scour valves follows key engineering principles:

At the lowest point: To ensure complete drainage.

At pipeline ends or dead-ends: To prevent stagnant water.

Before major equipment: Such as pumps or filters.

At intervals in long pipelines: For section-wise flushing.

Example:

In a 5 km water main, scour valves may be installed every 1 km or at each low point to remove sediments effectively.

Scour Valve Symbol vs. Air Valve Symbol

These two symbols often confuse beginners, but they serve opposite functions.

| Feature | Scour Valve | Air Valve |

|---|---|---|

| Purpose | To remove water or sediments | To release or admit air |

| Location | Lowest points of pipeline | Highest points of pipeline |

| Symbol Direction | Downward outlet | Upward outlet |

| Common Label | S.V. or Drain | A.V. or Air |

Tip: When reading drawings, look for the flow direction — downward for scour, upward for air release.

Common Applications of Scour Valves

Scour valves are used across various systems where liquid flow and sedimentation occur. Here are some key applications:

Water Supply Networks

Used in transmission and distribution mains to remove sediments that settle at low points.

Sewage Systems

To flush and clean pipelines during maintenance or blockages.

Dams and Reservoirs

Installed at bottom outlets to release water and sediments.

Industrial Piping

In chemical or thermal plants to drain process fluids safely.

Firefighting and Irrigation Systems

To clean lines and ensure reliable water delivery.

Benefits of Using Scour Valves

Improves water quality by removing dirt and sludge.

Prevents corrosion inside pipelines.

Reduces maintenance costs over time.

Protects pumps and valves from debris damage.

Extends lifespan of water infrastructure.

In short, the scour valve is small but mighty — ensuring clean, safe, and efficient operation in all fluid systems.

How to Read the Scour Valve Symbol in a Drawing

When you come across a scour valve symbol on a drawing:

Locate its position — usually at the lowest point or near a chamber.

Check the label — it may read “S.V.” or “Drain.”

Note the connection — it should link to a drainage outlet.

Understand the operation — it indicates where flow can be manually or automatically released.

If you see multiple scour valves in a system, they’re typically placed to enable sectional flushing, meaning each pipeline segment can be cleaned without shutting down the whole network.

Example Scenario: Scour Valve in a Water Distribution Line

Imagine a city water pipeline running through hilly terrain.

Water naturally collects at low-lying areas.

Over time, sand and silt settle there.

To keep the pipeline clean, engineers install scour valves at these low points.

When opened, these valves flush out dirty water into a drain or channel — keeping the system efficient and hygienic.

On the P&ID drawing, you’d see small valve symbols marked “S.V.” at those locations — that’s how technicians identify them during maintenance.

Maintenance of Scour Valves

Proper maintenance ensures reliability and smooth operation.

Routine Maintenance Checklist:

Open the valve periodically to flush sediments.

Inspect seals and seats for wear or leaks.

Lubricate the moving parts (if applicable).

Replace faulty parts or corroded sections.

Ensure outlet pipes are clear of obstructions.

Regular maintenance not only prevents failures but also ensures accurate representation on system maps and drawings.

Tips for Drawing or Reading the Scour Valve Symbol

Use standard symbols (ISO/ANSI) for clarity.

Always label the symbol as “S.V.” or “Drain.”

Position it at low points in the pipeline layout.

Ensure drain lines are directed to safe discharge points.

For automated systems, show actuators or controllers attached to the symbol.

These practices ensure consistent and clear engineering documentation.

Conclusion: Understanding the Scour Valve Symbol

The scour valve symbol might look simple, but it carries great importance in engineering design. It represents a vital component that keeps pipelines clean, safe, and efficient.

To summarize:

It’s used to drain and flush water systems.

Found at the lowest points of pipelines.

Shown as a valve symbol labeled “S.V.” or “Drain.”

Essential for maintenance, safety, and hygiene in water and industrial systems.

Whether you’re an engineer, drafter, or student, mastering the scour valve symbol helps you interpret drawings accurately, design better systems, and maintain pipelines more effectively.

Final Tip:

When reviewing or creating piping drawings, always double-check the placement and labeling of scour valves. A correctly positioned scour valve ensures a cleaner, safer, and longer-lasting water network.

Post Comment